PROTECT YOUR

WATER TANKS

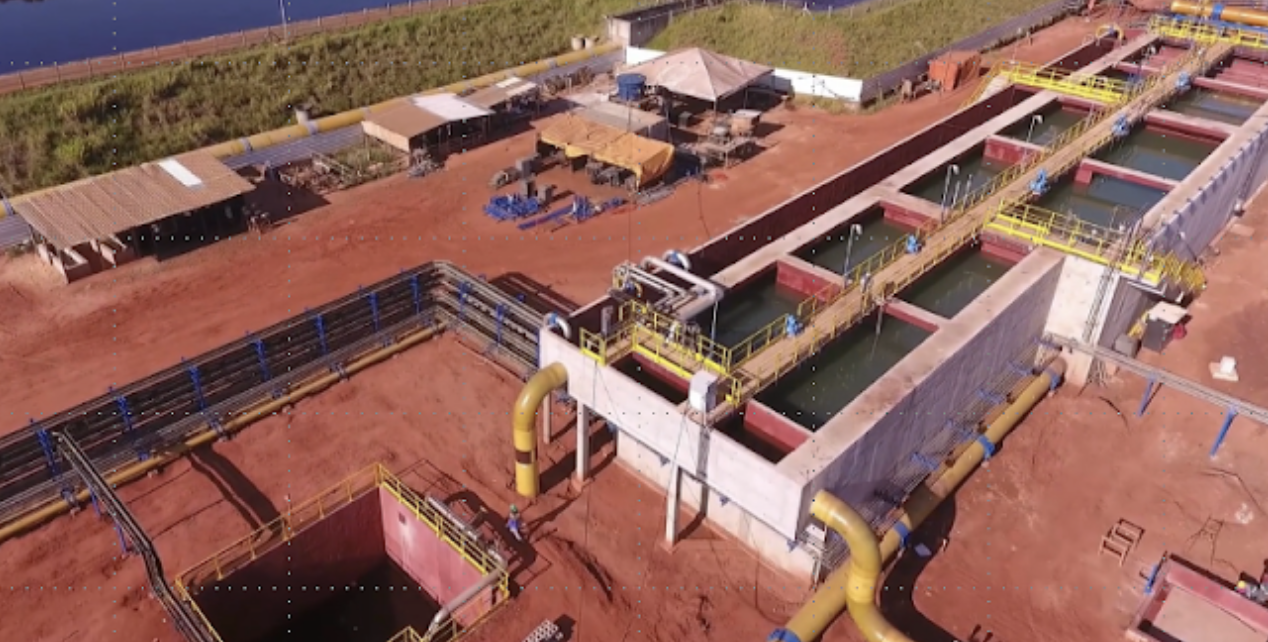

This newly constructed water treatment plant wanted to make sure the concrete tanks had the proper long-term protection to ensure they exceeded the design life the engineers had planned for them. The challenge facing the specifiers was to determine the fastest & most effective way to provide long-term waterproofing protection for this critical infrastructure facility.

WATER TREATMENT FACILITY

THOMPSON HOTEL - WATER RETENTION TANK

The challenge involved waterproofing the interior of a water containment tank in a newly constructed hotel in Denver's LoDo District. While cementitious coatings are commonly used, a spray-applied application forming a subsurface membrane was deemed appropriate for this project. After thorough evaluation, the Developer and Architect chose the TechCrete 2500 Waterproofing System for its unparalleled long-term protection, absence of VOCs, and potable water certification, ensuring effective waterproofing of the underground tank.

LEE HEIGHTS STORAGE TANK

The Lee Heights water storage tanks were built in 1957, with domed roofs made of structural concrete. The two tanks store a combined total of 6 million gallons of potable water for the use of the local community. Over the years, the concrete tanks had deteriorated to the point where several hundreds of thousands of dollars of repairs were required.

Once the rehabilitation work was completed, the challenge was to determine what the best long-term waterproofing solution was. The decision was made to use the award-winning TechCrete 2500 Waterproofing System by Alchemco, to protect the domed roofs on both tanks.

PURDUE UNIVERSITY - BRINE TANK

The deteriorated concrete brine tank servicing Purdue University's Tarkington Residence Hall prompted a structural engineering evaluation for rehabilitation. While polyurethane coating systems are standard, they offer only short-term performance. C.E. Solutions, the engineering company entrusted with the project, opted for the TechCrete 2500 Waterproofing System due to its proven success in previous Purdue projects, long-term durability, environmental friendliness, and Potable Water Certification, simplifying the choice of waterproofing solution.

HATFIELD’S & MCCOY’S DINNER THEATER

The Hatfield’s & McCoy’s Dinner Theater faced a unique challenge when their stage, designed to transform between a solid floor and a diving tank, began leaking water due to unprotected concrete. After nearly two years of constant water loss, the theater needed a quick and efficient waterproofing solution without disrupting performances. TechCrete 2500 Waterproofing System was chosen for its suitability on both vertical and horizontal surfaces, cost-effectiveness, and durability. The system was successfully applied in less than 48 hours, allowing the tank to be refilled and performances to resume promptly. Since the application, there has been no water leakage.